This page displays only the text of a material data sheet. Deflection Temperature at 1.8 MPa (264 psi), ASTM D648.Deflection Temperature at 0.46 MPa (66 psi), ASTM D648.

QuickCast™ patterns for investment casting.And applies separately to each account with a paid subscription (Customer) with Squadcast (Service Provider). Medical instruments, devices and labware This Squadcast Service Level Agreement (SLA) is a policy governing the use of Squadcast Web Application, Squadcast Mobile Applications (Android and iOS), Squadcast Notification Services, and Squadcast API services.Consumer electronics (cell phones etc.).For use with solid-state stereolithography (SLA®) systems. Simulate the properties and appearance of polycarbonate. This Is Why FEF! Foundry Educational Foundation 847.490.3D Systems Accura® 60 Plastic for SLA® Systems It is hands down the BEST.” November 16 & 17, 2017 Westin Michigan Avenue, Chicago, IL Register Today. I am blown away at the community FEF has established between Universities and companies in the industry.

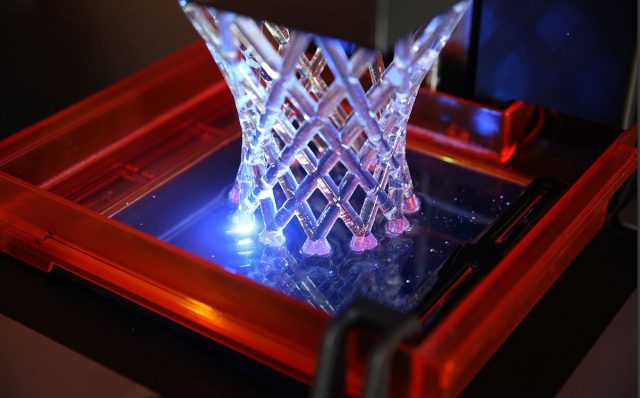

cultivates and creates opportunities for young people to get into the exciting and evolving foundry industry.” “. diameter part pattern could be produced with QuickCast on a 3D Systems ProX 800 Connect with 100+ of the brightest students seeking full-time and internship/co-op positions 2017 College Industry Conference Metalcasting’s career-resource and networking event “FEF. Large, Accurate Builds Andy Reeves, sales engineer for new business development, Vaupell, esti-mated that a specific 26-in. “It’s not economically sound to do iterative design prototyping with traditional wax molds,” Reeves said, “but QuickCast really lends itself to itera-tive design to support both the part and process development. If there is a mistake in the pat-tern or it does not perform as expected, it only takes a few days to create and print a new iteration, versus the weeks or months involved in modifying (or re-making) a wax mold. QuickCast patterns are much more accurate and can keep a tighter tolerance than any wax tool.” Reeves said the SLA process is for-giving. “You’re not cal-culating for the shrinking of the metal and the wax on top of it. “A big advantage of QuickCast over wax tooling is that you’re only calculating metal shrink,” Wong said. Less Shrinkage, More Iterations One of the challenges of invest-ment casting-calculating shrinkage during manufacturing-is lessened considerably by SLA. “We’re saving time on the post-print finishing because the finish of the resins is so good, and we’re also saving time from not having to build parts in two pieces and bond them together,” Wong said. (0.025-0.05 mm) per inch of part dimension-enables Vau-pell to meet the exacting requirements of its aerospace customers. Not only do you produce more in less time, but larger parts reduce labor costs-the fewer pieces, the fewer welds.” The accuracy of the ProX 800- 0.001-0.002 in. “You can do a larger piece in one run that would take two runs on a smaller machine. “The large platform is a great advantage over other machines,” said Austin Wong, rapid prototyping manager, Vaupell. (650 x 750 x 550 mm), providing flexibility and speed for a single build of a large part or for quick runs of multiple parts. The ProX 800 has a large print envelope of 25.6 x 29.5 x 21.65 in. The process is ideal for the aero-space market, which often requires low volumes of highly complex parts.

Vaupell is using QuickCast, the stereo-lithography (SLA) process developed by 3D Systems for investment casting, to deliver speed and quality to its custom-ers. But the workflow is changing rapidly, and one example is Vaupell (Seattle), a 70-year-old supplier of aerospace com-ponents and subassemblies and a more than 20-year veteran of 3-D printing. As a general rule, it is good practice to require that the pattern does not contribute more than 50 of the tolerance of the finished casting. During the past century, the process has benefited from many inno-vations, but still faces challenges such as production time and cost. SLA QuickCast is made from a UV curable polymer (epoxy resin). CASTING INNOVATIONS Stereolithography Process Leads to Savings for Investment Caster Traditional investment casting has been around for more than 5,000 years. Investment casting suppliers that we use prefer CastForm because it leaves less ash.

0 kommentar(er)

0 kommentar(er)